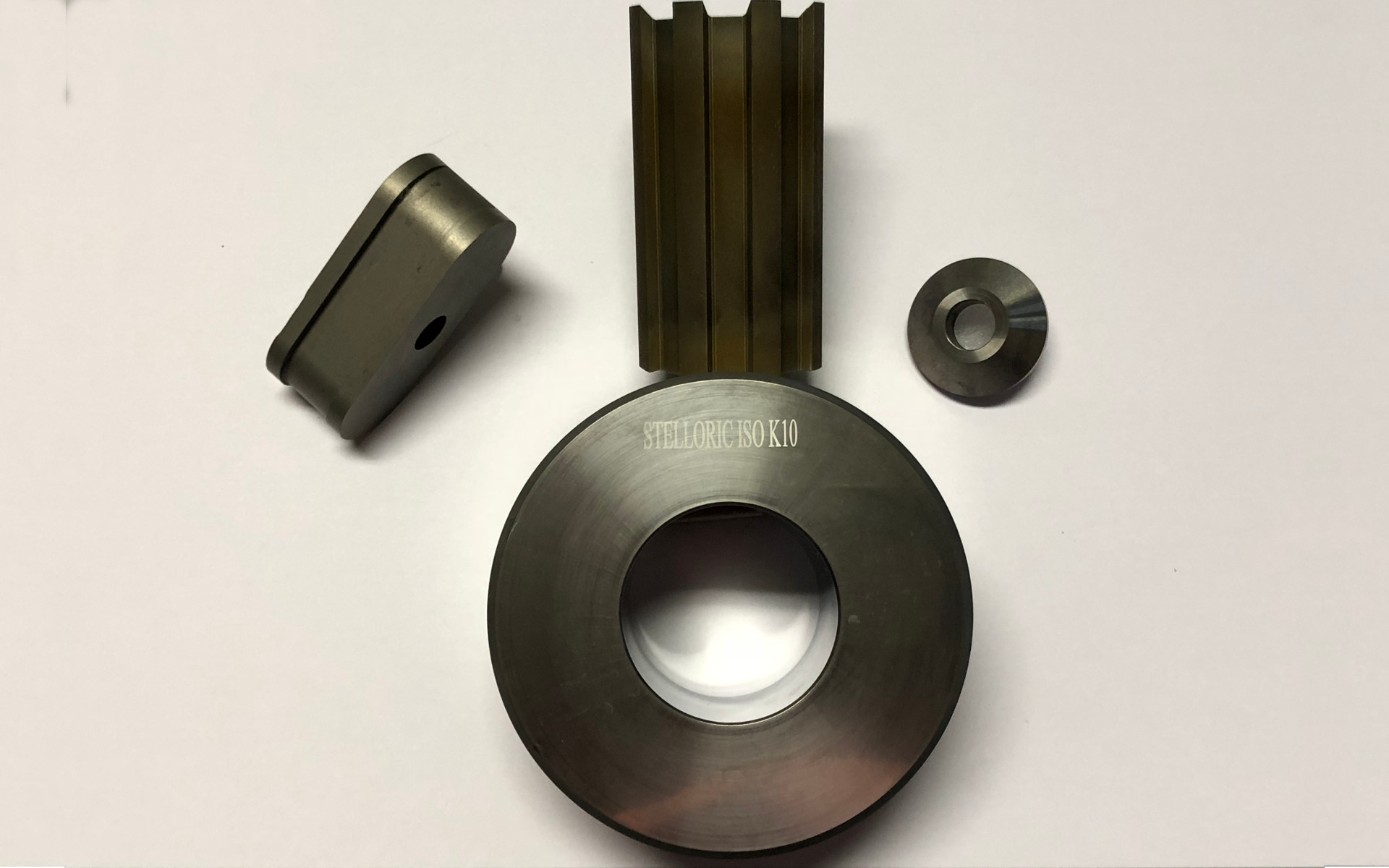

Tungsten Carbide alloys

ORIC Italiana S.r.l. produces and sells Tungsten Carbide alloys. These alloys have excellent resistance to wear, abrasion, erosion and are characterized by very high hardnesses. For these properties, Tungsten Carbide alloys are used where the conditions of use are particularly severe.

The Tungsten Carbide (WC) together with the Cobalt (Co) forms the basic structure of the carbide from which other types of hard metals have been developed. In addition to the first Tungsten Carbide of cobalt composition, the carbide may contain several percentages of titanium carbide (TiC), tantalum carbide (TaC) and niobium carbide (NbC).

- Mechanical parts

- Bars

- Coating material (Small Bars – Electrodes – Wires – Powders)

- Food: blades – rolls – seats

- Energy: sealing rings – bushings

- Wood: teeth – blades – tools

- Metallurgical: sealing rings – punches – rollers – moulds – tools

- Petroleum: shafts – bushings – shutters – seats

- Glass: rings – taps

Common types of Tungsten Carbide alloys:

| Stelloric ST01 (ISO K01) | HRa 93 | the hardest with the highest resistance to abrasion |

|---|---|---|

| Stelloric ST10 (ISO K10) | HRa 92 | excellent resistance to abrasion |

| Stelloric ST20 (ISO K20) | HRa 91 | excellent resistance to abrasion |

| Stelloric ST30 (ISO K30) | HRa 90 | good resistance to abrasion – tough |

| Stelloric ST40 (ISO K40) | HRa 89 | less resistance to abrasion – more toughness |

| Stelloric ST50 (ISO K50) | HRa 87 | resistance to abrasion – good bending strength |

| Stelloric ST37 (Special) | HRa 90 | Nickel with excellent resistance to corrosion – abrasion |

As for Stellite and Superalloys, Oric Italiana S.r.l. offers its advice in the choice of Tungsten Carbide alloys more adapted to their needs and in the production of custom-made components, designed by the customer.