Coatings and Weldings in Stellite and Superalloys

Oric Italiana S.r.l. has always focused on the activity of coatings and Stellite and Superalloys weldings.

The flexibility and professionalism of the staff allow the resolution of the various production problems quickly and are the fundamental elements of our activity.

Below is a list of services offered by Oric Italiana S.r.l. :

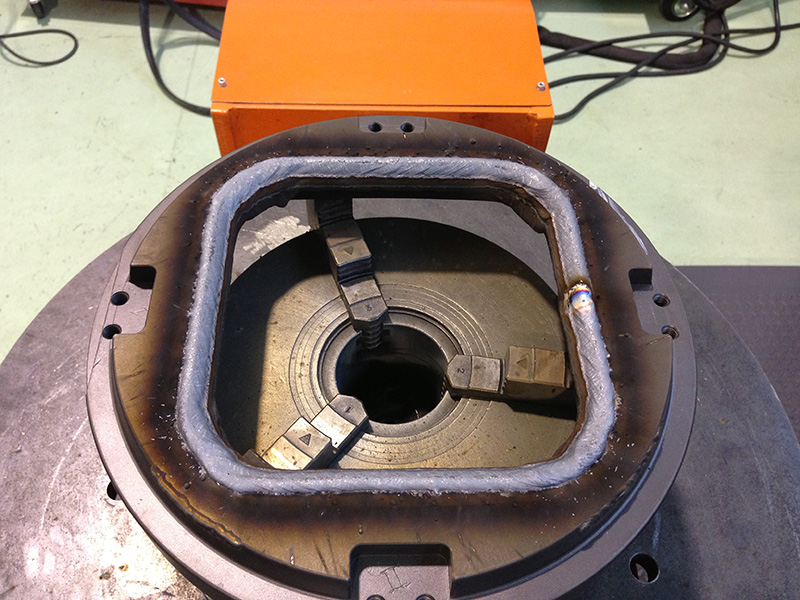

PTA (Plasma Transfer Arc)

PTA welding in Stellite or Superalloys is a process that uses plasma generated by an electric arc as a carrier gas. The transferred arc also casts the base material on which the molten powder is deposited. It is a high performance and production process.

SF (Spray Fuse)

SF welding in Stellite or Superalloys, is a process that includes two phases: the first is to spray powder on the surface of the piece with a flame gun and the second is to melt it with an oxyacetylene torch.

PW (Powder Weld)

PW welding in Stellite or Superalloys, is a process similar to the oxyacetylene deposit, but with the use of powder contained in a small hopper placed on the torch. Smooth and even deposits are obtained that require minimal mechanical processing.

OFW (Oxyfuel Gas Welding)

The OFW oxyfuel welding in Stellite or Superalloys is a welding process in which the energy is supplied by the combustion of acetylene. Filler material is almost always required, usually in the form of small bars, fluxes under the flame.

SMAW (Shielded Metal Arc Welding)

SMAW coated electrode welding in Stellite or Superalloy, that is, arc welding with shielded metal, is the most commonly-used welding technology in the world, thanks to the low costs and versatility of use.

GTAW (Gas Tungsten Arc Welding)

TIG welding in Stellite or Superalloys, is an arc welding process with an infusible tungsten electrode, under the protection of inert gas. It is one of the most commonly-used methods; it provides high quality, but requires highly skilled operators.

HVOF (High Velocity Oxygen Fuel)

HVOF welding in Stellite or Superalloys, is a cutting-edge process for powder deposits. Thanks to the high speed of the gas (>2000m/s) and dust (>1000m/s) excellent anchors are obtained, reduction of porosity and superior quality, without affecting the characteristics of the base metal.

LASER

LASER welding in Stellite or Superalloys, is a welding technique used to join or carry over pieces of metal with the use of a laser. The beam provides a concentrated heat source and allows thin, deep welding.

GMAW (Gas Metal Arc Welding)

MIG Arc welding with metal under gas protection, in Stellite or Superalloys, is an increasingly widely used welding process. The main reasons for its development have been cost reduction and the possibility of using electronics.

SAW (Submerged Arc Welding)

SAW submerged arc welding in Stellite or Superalloys is a continuous wire arc welding process under slag protection. This type of welding lets you operate with high speeds and deposit and is a process that can be completely automated.

Do not hesitate to contact our offices for any information.