Mechanical Machining in Stellite and Superalloys

In recent years, the evolution of the market underpinned by the technological drive and innovation, together with the know-how and solid investments of the ORIC group, has allowed the creation and development of an internal workshop for highly specialized, cutting-edge mechanical machining, which can offer customers a wide choice of production processes of Stellite components and Superalloys.

The continuous updating and experience of the staff allow Oric Italiana S.r.l. to solve the most difficult problems related to the machining of Stellite and Superalloys.

The company is able to offer the following services:

CNC Turning

Machining of Stellite and Superalloy components with numerical control and automatic lathes able to satisfy the most extensive finishing requests.

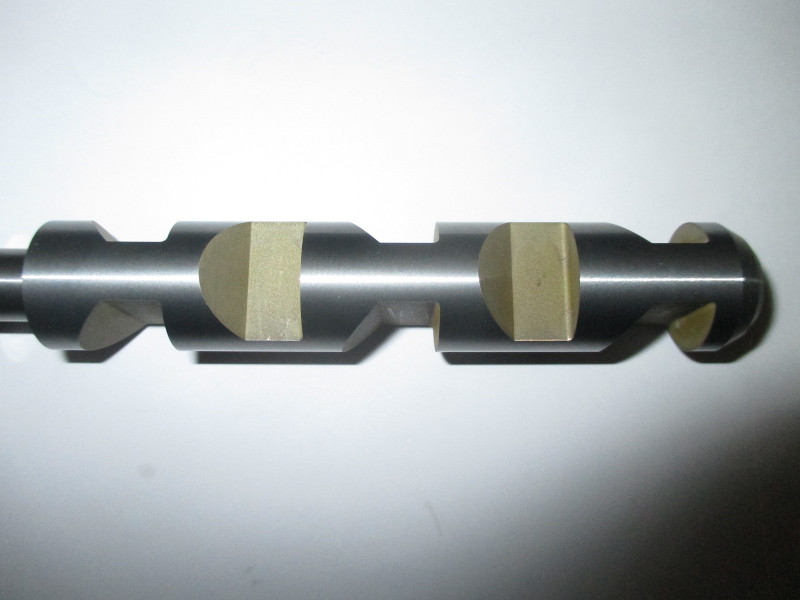

CNC Milling

Machining of Stellite and Superalloy components with numeric control and manual machining centres for the most complex geometries.

CNC Grinding

Machining of Stellite and Superalloy components with numerical control grinding, where, for the hardness of the pieces, it is not possible to use other machine tools.

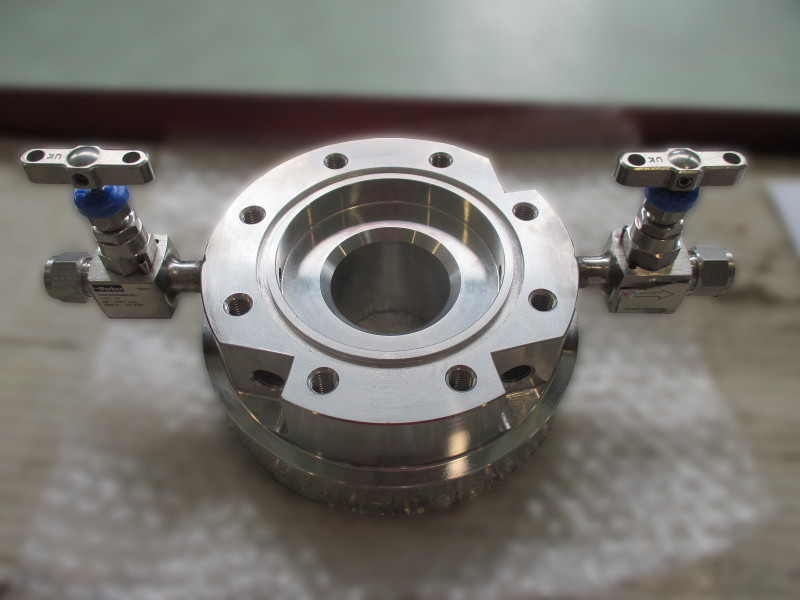

Assembly

Assembly of Stellite and Superalloy components produced at our workshop or provided by the customer.

Heat Treatments

We have an automatic temperature control oven to perform heat treatments where required on Stellite and Superalloy parts

Non Destructive Controls

Penetrating Liquids – Ultrasound Controls – X-Rays on Stellite and Superalloy parts with qualified and certified internal staff, as well as the use of the advice of a Sincert-certified external testing laboratory, with which Oric Italiana S.r.l. has been working for a long time.